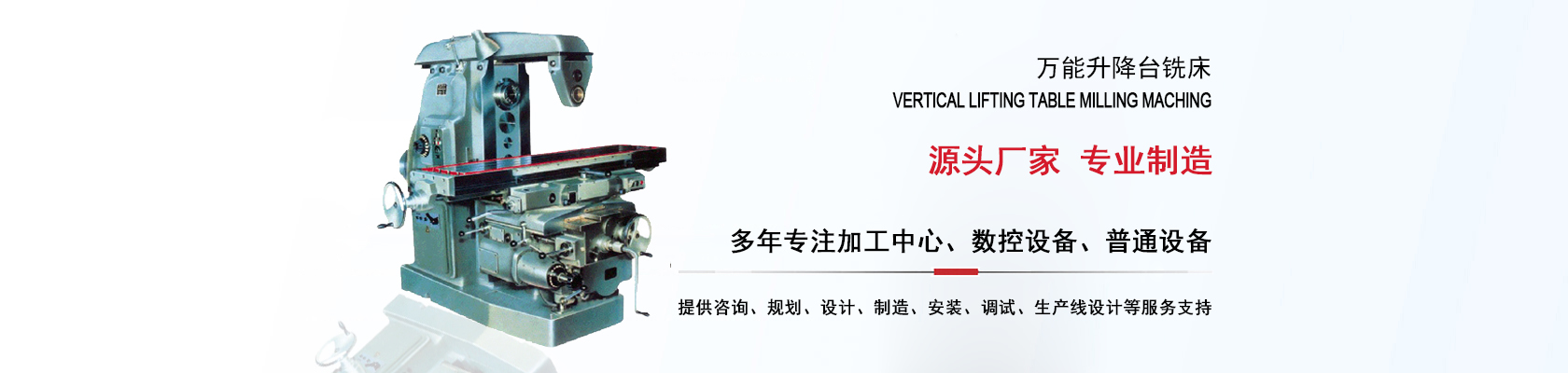

X8132适用于仪器仪表制造工厂作成批生产零件使用,亦适用于工具及制造车间、修理车间以及科学研究单位铣削各种工具、夹具、冲模及形状的小型零件。本机床主轴采用双列向心短圆柱滚子轴承,精度高,调整方便。机床采用双速电动机,变速范围广,转速又高,故使用时有很高的生产率。

机床附件主要有:立铣头、分度头、圆盘台面、角度工作台及台虎钳,因此性强,用途广泛。

| 工作台 | 水平工作台面积(长x宽) | Working | Horizontal Working table ( L x W) | 320x750mm |

| 垂直工作台面积(长x宽) | table | Vertical Working table ( L x W) | 250x850mm | |

| 行程: 纵向、横向、垂向 | Longitudinal/Transverse/vertical Travel | 400/300/400 | ||

| 水平和垂直主轴转速级数/范围 | Horizontal and vertical spindle speed :steps/range | 18 steps(级)/40~2000rpm | ||

| 纵向,横向,垂向进给量:级数/范围 | Longitudinal,transverse and vertica feeds: | 18 steps(级)/10~500min | ||

| steps/range | ||||

| 立铣头套筒轴向进给量:级数/范围 | Axial feed of quill of vertical spindle steps/range | 3 steps(级)/0.03~0.12mm/rev | ||

| 套筒轴向行程 | Vertical | Vertical travel of quill | 60mm | |

| 立铣头 | Spindle head | |||

| 轴线左右倾斜 | Axia inclination left and right | ± 90° | ||

| 内锥孔 | Taper hole | ISO40 | ||

| 水平主轴 | 中心线至地面高 | Horizontal | The height from axis to ground | 1330mm |

| 中心线至水平工作台面最小距离 | spindle | Min ,distance between axis and | ||

| surface of Horizontal table | 40mm | |||

| 内锥孔 | Vertical | Taper hole | ISO40 | |

| 垂直主轴 | 端面至水平工作台面最小距离 | Spindle | ||

| Min ,distance between nose and | 10mm | |||

| Surface of horizontal | ||||

| 水平回转 | Horizontal swivel | ± 360° | ||

| 工作台 | 前后向倾斜 | Universaltable | Inclination to front and rear | ± 30° |

| 左右向倾斜 | Inclination on left and right | ± 30° | ||

| 主电机/进给电动机功率 | Power of main motor/Feed motor | 3kw/1.5kw | ||

| 更大承载工件重量/刀具更大负荷 | Max. table load/Max. load of cutter | 300kg | ||

| 机床外形尺寸(长x宽x高)/净重 | Overall dimensions ( L x W x H)/Net weight | 181x122x171cm/2200kg | ||

| 包装箱尺寸(长x宽x高)/毛重 | Packing dimensions ( L x W x H )/Gross weight | 200x164x210cm/3000kg | ||

全国服务热线

全国服务热线